Production

Process control

We established a strict regulations for production, reasonable production control, efficient and duly production management, BOM system, the active promotion of computerizing management, control of materials for the purchase orders. The operation management system, MRP and ERP are adopted, which is able to control exactly from order, displacement of labor, procedure of manufacture, trace procedure, control of production schedule. All of this may meet OEM request.

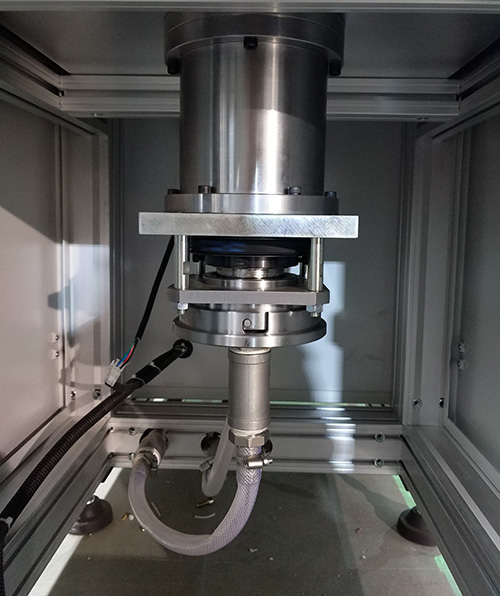

Maintenance of equipment

• Automatic metal round sawing machine

• Automatic hole-deepening processing machine

• CNC automatic lathe

• Box carbon infiltration furnace

• CNC cutting machine

• Hollow grinder

• Liquid sand spurting machine

• Two-end face rubbing machine

• Profilometer, Metallurgical microscope, Microhardness teste

Conform to demands, customer first, quality first, continuous improvement

Quality

We have passed ISO 9002, QS-9000, and TS-16949.

We insist in TOYOTA 6S lean management system.

QUALITY CONTROL: 100% MPI test

Quality control

Inspect: raw materials, arrival of materials, process and finish goods.

We make use of all kinds control method, such as: CPK control, defects control, in order to assure that our prodcuts are conformed to the quality request. We keep the quality management of the process, trace of products, other related quality information and records completely on file, so that we can provide a professional consulting service to the quality.

Maintenance of Inspection Instrument

To assure the precision of the measuring instrument and its life span, the instrument should be maintained and corrected regularly by professional staffs.

The related correction of quality could be traced to the national laboratory.

To lessen the error of measurment, the cylinder measuring machine and surface roughness meter should be placed at the quality assurance laboratory (temperature and humidity are controlled day and night).

We take charge of the supervision of quality, they inspect every step before delivery, such as; purchase of raw materials, arrival of materials, process and finish goods.

We make use of all kinds control method, such as: CPK control, defects control, in order to assure that our products are conformed to the quality request.

Inspection Instruments

- Spectrometer ARL3460 : USA ThermoFisher Scientific

- Cylinder measuring machine 360: JAPAN

- Surface roughness meter JB-6C: CHINA

- Metallurgical Microscope

- Electric-measuring-instrument: MAC-1

- Profile meter MMD-100

- Micro hardness meter

Workshop & Equipment

ITEMS |

SCOPE |

INSTRUMENTS |

CAPABILITY |

|

1 |

Outer diameter |

-0.002mm~-0.004mm |

Outer diameter measuring Instrument |

± 0.0005 mm |

2 |

Length |

+0mm~0.20mm |

Vernier calipers |

± 0.01 mm |

3 |

Carburized deep |

According to the specification |

Micro-hardness gauge |

± 0.02 mm |

4 |

Surface hardness |

HRA 80~84 |

Rockwell hardness meter |

± 0.1 |

5 |

Core hardness |

HRC 32-46 |

Rockwell hardness meter |

± 0.1 |

6 |

Surface roughness |

Under Rz 0.8(0.8s) |

Surface roughness meter |

± 0.0001 µm |

7 |

Cylinder grinding |

2µm- 5µm |

Cylinder meter |

± 0.001µm |

8 |

Real straightness |

Less than 0.002 mm |

Cylinder meter |

± 0.01 µm |

9 |

Carburized structure |

Residual austenite be less than 8% |

Metallurgical microscope |

Visual c |